With the cooperation of the local commercial

farms, Maruei Inc. supplies our customers with

products under our philosophy "safety",

"security", and "consistency".

|

|

The entire process from receiving materials to

shipping products is in an out carried thorough

hygiene crisis management environment. All

operations are completed in three strictly

sectioned rooms during production. After being

processed, our products are stored and finally

shipped through four strictly sectioned rooms.

(HACCP is the system that analyzes hygienic and

quality hazards which might occur in the

production process. It controls and records the

entire process strictly by monitoring critical

control points.) |

|

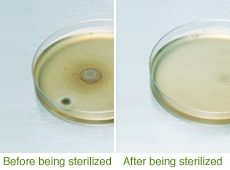

This high pressure sterilization never ruins the

flavor and never distorts the color of our tea

leaves. The sterilization can be also used in a

wide variety of food products such as dried

vegetables and health food. (Daily output:

3,000kg)

|

|

| before sterilization |

|

after sterilization |

|

general living bacteria |

heat resistance bacteria |

coliform bacteria |

moisture |

general living bacteria |

heat resistance bacteria |

coliform bacteria |

moisture |

| tea leaves |

8.0 x 103 |

4.8 x 103 |

(-) |

3.70 |

< 20 |

< 20 |

(-) |

5.50 |

| mulukhiya power |

4.8 x 106 |

8.0 x 105 |

(+) |

6.30 |

3.4 x 102 |

1.6 x 102 |

(-) |

5.20 |

| dried green onion |

2.2 x 104 |

2.0 x 102 |

(+) |

9.30 |

< 20 |

< 20 |

(-) |

10.90 |

|

|

Our all-in-one device can mill and classify tea

leaves simultaneously, without losing aroma.

Maruei Inc. can mill each order into any grain

size according to the customer's needs.

( Daily milling capability: 800kg) |

|

|